Optimal Timing for Electrostatic Painting

Electrostatic paintings are most effective when applied under specific environmental conditions. Optimal timing depends on factors such as humidity, temperature, and surface readiness. Proper timing ensures adhesion, finish quality, and durability of the coating.

The best temperature for electrostatic painting is typically between 65°F and 85°F (18°C - 29°C). Temperatures outside this range can affect paint adhesion and curing.

Low humidity levels, generally below 50%, are preferred to prevent moisture from interfering with the electrostatic process and to achieve a smooth finish.

Timing surface preparation to occur just before painting ensures surfaces are clean, dry, and free of contaminants for optimal electrostatic adherence.

Dry, calm weather with minimal wind and no rain is ideal for outdoor electrostatic painting projects to prevent debris and moisture interference.

A technician applying electrostatic paint with specialized equipment.

Cleaning and prepping surfaces before electrostatic painting.

A smooth, evenly coated surface post-application.

Ways to make Electrostatic Paintings work in tight or awkward layouts.

Popular materials for Electrostatic Paintings and why they hold up over time.

Simple add-ons that improve Electrostatic Paintings without blowing the budget.

| Factor | Optimal Conditions |

|---|---|

| Temperature | 65°F to 85°F (18°C - 29°C) |

| Humidity | Below 50% |

| Wind Speed | Calm, minimal wind |

| Surface Dryness | Completely dry surface |

| Rain | No rain or moisture |

Electrostatic paintings utilize an electric charge to attract paint particles to surfaces, resulting in efficient coverage and minimal overspray. This method is widely used in industrial, commercial, and automotive applications for its high-quality finish and environmental benefits. Proper timing of application enhances the process by ensuring ideal environmental conditions, which directly impact the adhesion, finish, and longevity of the coating.

High-voltage electrostatic spray gun in use.

Surface cleaning and priming before painting.

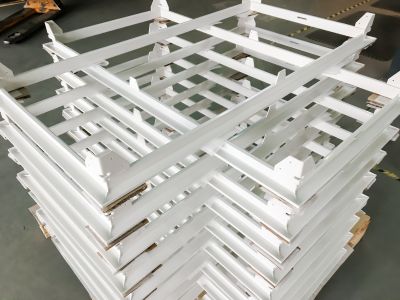

Electrostatic painting on large metal structures.

Finished electrostatic painted surface.

Scheduling electrostatic painting during favorable environmental conditions ensures maximum efficiency and quality. Proper timing reduces rework, enhances finish consistency, and extends the lifespan of the coating. Awareness of local weather patterns and surface conditions is essential for successful application.